Live Tides

NOTICES TO MARINERS

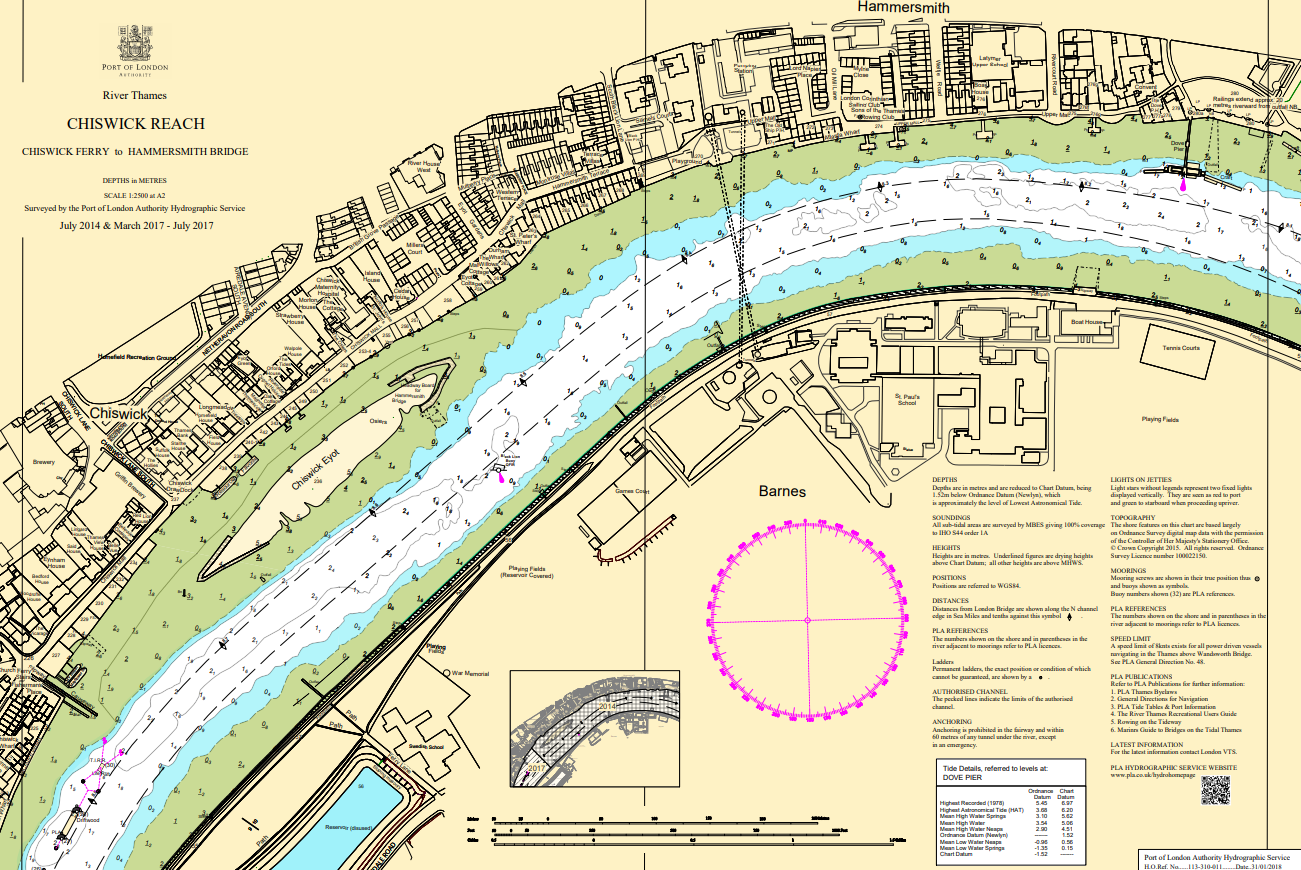

Charts & Surveys

Incident reporting

Life-threatening emergencies on the river:

Call 999 and ask for the Coastguard

For near miss, safety observations and incident reporting click below

Thames Freight Standard

Technical standards for commercial vessels on the tidal Thames

Baseline Document for Maintenance Dredging - June 2007

This Statement has been prepared in accordance with section 35 of the Pensions Act 1995 (as amended by the Pensions Act 2004, and the Occupational Pension Schemes (Investment) Regulations 2005).

The effective date of this Statement is 30 September 2025. The Trustees will review this Statement and the Scheme’s investment strategy no later than three years after the effective date of this statement and without delay after any significant change in investment policy.

Engagement Policy Implementation Statement

On 6 June 2019, the Government published the Occupational Pension Schemes (Investment and Disclosure) (Amendment) Regulations 2019 (the "Regulations"). The Regulations require that the Committee produces an annual implementation statement which outlines the following:

- Explain how and the extent to which they have followed their engagement policy, which is outlined in the SIP.

- Describe the voting behaviour by, or on behalf of the Committee (including the most significant votes cast by the Committee or on their behalf) during the Fund year and state any use of the services of a proxy voter during that year.

This document sets out the details, as outlined above. The Engagement Policy Implementation Statement has been prepared by the Committee and covers the period 1 April 2024 to 31 March 2025.

This Statement has been prepared in accordance with section 35 of the Pensions Act 1995 (as amended by the Pensions Act 2004, and the Occupational Pension Schemes (Investment) Regulations 2005).

The effective date of this Statement is January 2025. The Trustees will review this Statement and the Scheme’s investment strategy no later than three years after the effective date of this statement and without delay after any significant change in investment policy.

Engagement Policy Implementation Statement

This document sets out the actions undertaken by the Trustees, its service providers and investment managers, to implement the stewardship policy set out in the Statement of Investment Principles ("SIP"). The document includes voting and engagement information that has been gathered from the asset managers and an overview of how the policies within the SIP have been implemented during the reporting period. This is the engagement policy implementation statement the Trustees have prepared and covers the year ending 31 March 2025.

This Statement has been prepared in accordance with section 35 of the Pensions Act 1995 (as amended by the Pensions Act 2004, and the Occupational Pension Schemes (Investment) Regulations 2005).

The effective date of this Statement is May 2025. The Committee of Management ("the Committee") will review this Statement and the Fund's investment strategy no later than three years after the effective date of this statement and without delay after any significant change in investment policy.

Engagement Policy Implementation Statement

On 6 June 2019, the Government published the Occupational Pension Schemes (Investment and Disclosure) (Amendment) Regulations 2019 (the "Regulations"). The Regulations require that the Committee produces an annual implementation statement which outlines the following:

- Explain how and the extent to which they have followed their engagement policy, which is outlined in the SIP.

- Describe the voting behaviour by, or on behalf of the Committee (including the most significant votes cast by the Committee or on their behalf) during the Fund year and state any use of the services of a proxy voter during that year.

This document sets out the details, as outlined above. The Engagement Policy Implementation Statement has been prepared by the Committee and covers the period 1 April 2024 to 31 March 2025.

Port of London Authority Pension Fund

Statement of Investment Principles

This Statement has been prepared in accordance with section 35 of the Pensions Act 1995 (as amended by the Pensions Act 2004 and the Occupational Pension Schemes (Investment) Regulations 2005)

The effective date of this Statement is February 2025. The Committee of Management ("the Committee") will review this Statement and the Fund's investment strategy no later than three years after the effective date of this statement and without delay after any significant change in investment policy.

Engagement Policy Implementation Statement

On 6 June 2019, the Government published the Occupational Pension Schemes (Investment and Disclosure) (Amendment) Regulations 2019 (the "Regulations"). The Regulations require that the Committee produces an annual implementation statement which outlines the following:

- Explain how and the extent to which they have followed their engagement policy, which is outlined in the SIP.

- Describe the voting behaviour by, or on behalf of the Committee (including the most significant votes cast by the Committee or on their behalf) during the Fund year and state any use of the services of a proxy voter during that year.

This document sets out the details, as outlined above. The Engagement Policy Implementation Statement has been prepared by the Committee and covers the Fund year from 1 April 2024 to 31 March 2025.

Health, safety and wellbeing policy

We are committed to protecting the health, safety and wellbeing of our employees and aspire to influence the wider river community and those who work with us

Supplier code of conduct

Consistent with our commitment to conduct business fairly and honestly, we seek out business partners who share in our culture, values and business practices

Sanctions policy

We will act reasonably to comply with all sanctions applicable to our business activities and that we appropriately manage associated risks

Quality policy

We aim to perform all our duties in a timely, positive and cost-effective manner, balancing the needs and expectations of interested parties.

Discover